About Us

Alba Ultrasound was formed in 2000, with the aim of becoming a world-leader in the field of ultrasonic transducers for sonar applications.

The company was founded on strong links between academia and industry, forging a unique blend of innovative Research and Development combined with robust manufacturing processes. These are principles the Company continues to this day, investing significantly in research programs to ensure we maintain our technological advantage, whilst continually improving our manufacturing processes and equipment.

Alba Ultrasound has a proven track record in defence and commercial market sectors, and has established significant working partnerships with worldwide sonar system manufacturers. We produce bespoke ultrasonic transducers and arrays, employing innovative design and manufacturing techniques. Throughout our history, we have consistently delivered high-quality and reliable products.

Pioneering designs and manufacturing techniques

Alba Ultrasound provides its design and operations capability from our state-of-the art headquarters in Glasgow, UK. Our facility comprises of over 13,000sq.ft. covering research, design, manufacturing and test processes. This enables us to repeatably produce high quality reliable products.

Our pioneering designs and manufacturing techniques produce a full range of complex sonar types including Multi-Beam Echosounders, Synthetic Aperture Sonar, Intruder Detection, Sidescan and imaging sonars. Our in-depth understanding of materials and processes allows us to manufacture reliable transducers for operation in the most demanding and harsh environments, including full ocean depth (>6000 metre) rated systems.

With a well-respected international reputation, Alba has positioned itself at the forefront of the underwater sonar sector. Our proven expertise has provided the company with a powerful platform to continue exceeding our partner’s expectations as our journey continues.

Our Facility

Design & Engineering

We have a dedicated team of Engineers who produce the acoustic and mechanical aspects of our designs using a range of analytical models, finite element analysis and CAD modelling techniques.

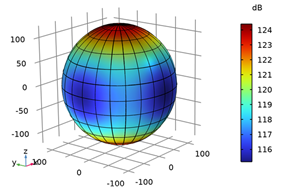

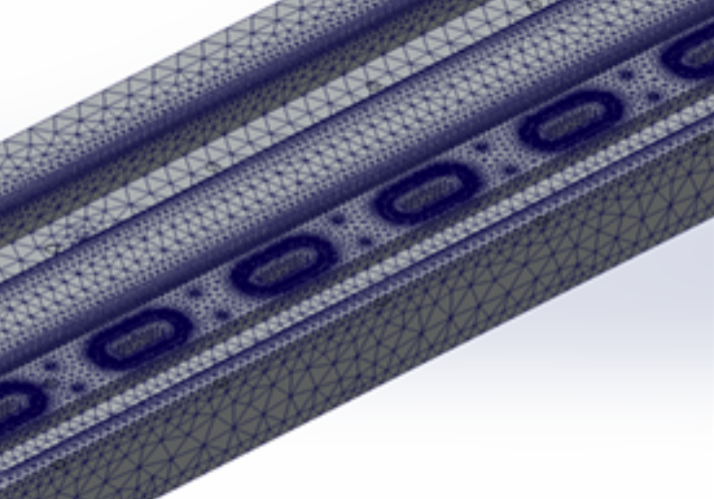

Acoustic Finite Element Analysis

Our experienced Acoustic Design team has expertise in the use of Finite Element Analysis (FEA) to simulate the performance of the entire transducer assembly. This includes the active piezocomposite elements as well as the critical role played by the passive polymer materials included in the transducer structure. This allows performance parameters such as internal strain behaviour, or pressure field mapping to be simulated and visualised, as in the images below. With a detailed understanding of the material properties and behaviour, this “virtual prototyping” can significantly reduce the lead-time to delivery of the first unit for customer qualification and trials.

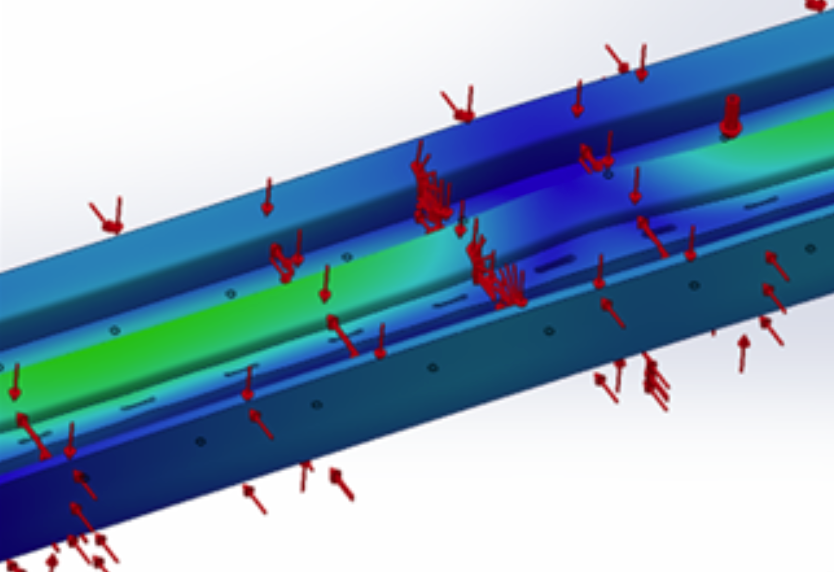

Mechanical Finite Element Analysis

Our skilled Mechanical Design team has been integral in Alba’s record of robust and reliable designs. One key feature of any sub-sea design is its ability to operate while exposed to the significant pressure experienced by our designs during deployment in the deep ocean. This requires that the designs not only survive this exposure, but also must retain the structural stability required to allow mechanical phase performance to be maintained in complex multi-element arrays. Through use of Solidworks FEA, this performance can be simulated and de-risked prior to manufacture of the design.

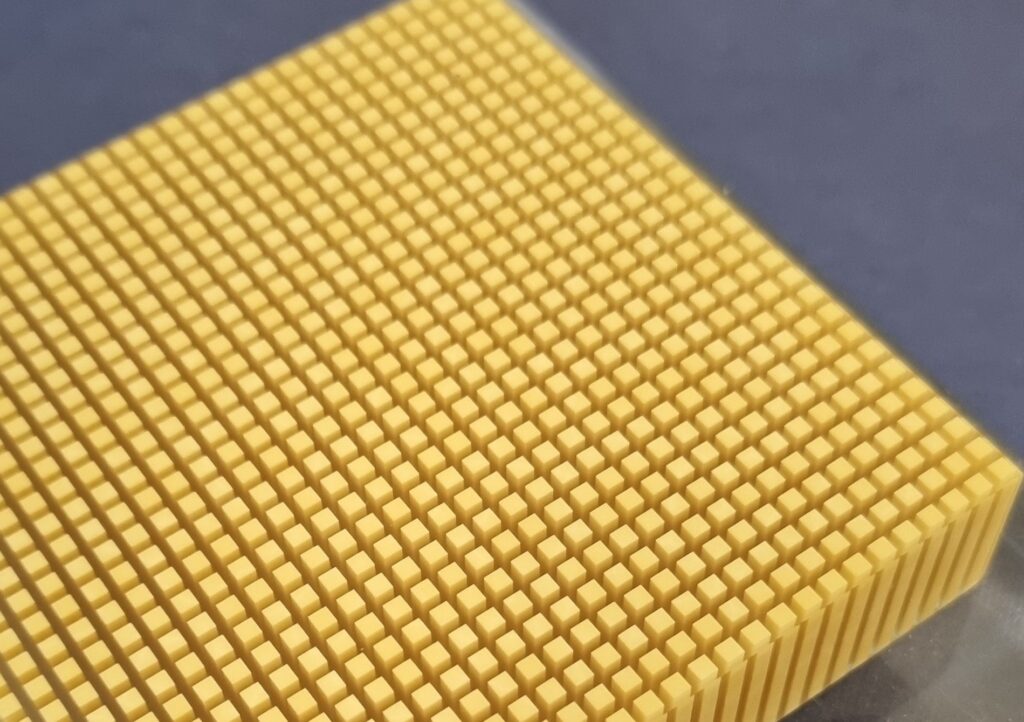

Piezocomposite dicing and grinding

Using state of the art automated equipment, we manufacture all our bespoke piezocomposite elements for each sonar design.

Polymer processing

The polymer materials required for piezocomposite performance and underwater marinization are processed and controlled through automated procedures and equipment.

Transducer Assembly

Each design is assembled by our team of trained technicians using a bespoke range of tools and fixtures specifically detailed for each process.

Precision CNC Machine Shop

All materials and structures required for manufacturing our sonar arrays and transducers are precision-machined in our on-site machine shop.

Acoustic Test

We have two test tanks allowing beam patterns and sensitivity to be measured for each of our designs.

Reliability Engineering

As a Company we pride ourselves on the reliability of our designs, performing in harsh environments over significant time periods. This performance is verified in-house using our automated pressure and thermal chambers.

Meet the Team

Victor Murray

Managing Director

Vic has extensive design experience in the sonar transducer industry, and played a significant role in pioneering the application of wideband piezocomposite transducer technology in underwater sonar systems. Under his leadership, Alba has become a renowned world leader in this area.

Duncan McMurdo

Operations Director

Duncan joined Alba in 2009 bringing expertise in manufacturing processes, supply chain and project management. Duncan provides leadership across all aspects of the business operations by directing a management team covering quality, manufacturing and material supply chain activities.

Simon Whiteley

Technical Director

Simon joined Alba in 2011 after completing his Ph.D. at the University of Strathclyde, researching the methods and processes used by bats using ultrasound for echolocation. His first project in Alba was to manage the SAMDIS sonar development for the Thales Maritime Mine Countermeasure (MMCM) program. Simon now heads up a team of engineers who cover the mechanical, acoustic and polymer design aspects of our underwater transducers.